PREV ARTICLE

NEXT ARTICLE

FULL ISSUE

PREV FULL ISSUE

VOCABULARY TERM: LACQUERDick Johnson submitted this entry from his Encyclopedia of Coin and Medal Terminology. Thanks. -Editor

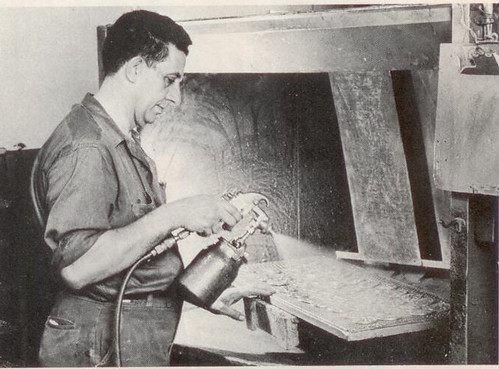

Spraying medals with lacquer in a spray booth along with baking under heat lamps to dry the lacquer are last steps in manufacturing art medals. Lacquer. A spirit varnish or shellac, clear or colored, which when applied to a medallic surface: (1) gives protection, (2) adds reflective or matte finish, (3) adds any metallic color, and (4) prevents tarnish. A thin application – even a few thousandths of an inch – forms a tough, durable, coating. Lacquer is fast drying and when thoroughly dried it is impervious to a wide range of environments and chemicals, making it ideal for the protection of medallic items or even a coin. Two types exist: natural lacquer (Japanese, Chinese varnishes) made from tree sap diluted and colored with pigments; and synthetic or artificial lacquer which have a variety of chemical bases (most popular are pyroxylin, resins, ester gum, cellulose acetate); these lacquers dry rapidly forming a hard, durable surface. Two other types also exists: air dry force dry lacquer and baked acrilic. All are forms of ORGANIC COATING. Art medal lacquering is required for protection of the surface. This is a function of the finishing department where it is performed with a spray gun in a spray booth (the booth prevents the spray mist from entering adjacent atmosphere). This is in contrast to the sculptural technique of surface metal protection of waxing, where a light coating of clear wax is applied to the surface. Artists creating art medals in their own studio can accomplish a lacquer coating with a spray can of lacquer where a spray gun, and spray booth, are not available. What needs to be lacquered. Metal items that have been formed and finished need to be lacquered to preserve the finish or patina that had been applied to their surface. Copper and bronze objects are the greatest candidates for lacquering because their surface is so unstable (look how fast a red copper coin turns brown). Gold, at the opposite extreme, needs little lacquer at all because it is so inherently stable. Bronze and silver art medals are lacquered for the reason to protect the surface that has been OXIDIZED and RELIEVED. The lacquer protects the color, the metal surface, and prevents undesirable TARNISH and TONING. Lacquering can also provide a GLOSS or SATIN FINISH. How lacquer is applied. Formerly any item to be coated with lacquer was brushed on or dipped. Generally too much lacquer adheres to the object when either of these methods were used, thus the application by modern spray gun is far more desirable. A coating so thin it is imperceptible to the naked eye but thick enough for protection can be sprayed. Even so, the amount of lacquer applied is a matter of personal taste, but too thick a coat becomes unsightly as it tends to build up in crevices and detail on numismatic items. A rule of thumb is thinner is better; two passes of the spray gun (one horizontal, one vertical) is sufficient. Medallic items are laid out on wire racks large enough for a dozen or so medals to be placed. This is carried to a spray booth, laid flat inside on a turntable. After one pass of the spray gun is directed over the medals the turntable is rotated one-quarter turn. The second pass is made over the medals (this provides both vertical and horizontal spraying). A second wire rack is placed on top of the medals and with both hands holding the two racks tightly together, the operator brings these out of the spray booth, and flips them over (without, of course, spilling any of the medals). Replaced in the spray booth, the top rack is removed and the second side is capable of being sprayed without humans ever having to touch the items. The wire rack containing the medals lacquered on both sides is then set aside to allow a thorough drying. To speed up the drying the tray of medals can be placed under heat lamps. Since this is usually a last step of production (unless the items must be suspended or fabricated in some other way), the wire rack is carried to the inspection table, after which the items are packaged. Mechanical spray lacquering. Some medal makers have attempted to mechanize the step of lacquering since it is labor intensive. Equipment developed for the continuous flow spray processing of license plates has been adapted for medal production but this has not met with full success. The application of lacquer by a spray gun manned by a human operator is as much an artistic factor as the choice of patina color. Lacquer as a coating. Once dried, lacquered objects become resistant to acids, alkalis, alcohol, and even heat up to 160° Centigrade (above this temperature, lacquer turns purple, then will strongly tarnish the item – FIREDAMAGED). Lacquered items are still protected with normal handling as the surface is impervious to perspiration and other contaminates found on the hands. Only when lacquered items are subjected to the strongest of solvents – as with benzene – will the lacquer be dissolved. After medallic items have been lacquered they can be handled with human hands for all time, an important advantage of lacquering. The protected surface of art medals, for example, do not need to be embedded, encapusalted, housed in plastic, slabbed, or otherwise entombed. Lacquering provides this condition for touching and open display. Lacquer as a reflective and coloring agent. Lacquer can change the reflectiveness or color of a finish, ranging from highly lustrous to a matte, from glossy to SATIN FINISH or less polished appearance. Pigments can be added to a clear lacquer to give a color tint to any item coated with that lacquer, as a GOLD TINT lacquer can be sprayed on any item. To achieve a MATTE surface the medallic item can be heated slightly and sprayed with a light coat of lacquer. Since the previous step is a complete drying of the metal surface, this is done under heat lamps. Thus it is ideal to spray immediately after removing from under the heat lamps. A minimum number of passes with the spray gun is necessary. For a more glossy, more reflective appearance the number of spray passes is increased, a thicker coating of lacquer is applied. This will give gloss to the surface, heated or room temperature, as the lacquer becomes more visible. Also, by adding BRONZE POWDERS to lacquers a metallic finish can be applied. Despite the name, bronze powders can be added to lacquer to imitate any metallic color, as bronze powders can be made of any metal – even aluminum or brass – which, when sprayed on an item give it a gray or gold color. Lacquer anomalies. Most problems with lacquer are derived from moisture. If moisture contaminates the lacquer and then sprayed on a medallic item, it may appear cloudy, called bloom in the art field. On the other hand if moisture is left on an object which is lacquered, a dark WATER STAIN will appear after about two year’s time. Undesirable lacquering occurs when too much lacquer has been applied. It tends to pool, or build up in the crevices and at the edges where relief meets the field in both the device and lettering. This is not pleasing to the human eye. Lacquer refurbishing. If any lacquered medal is dirty, dusty or has some grime, it may be cleaned with dilute soap solution, rinsed with lukewarm water and patted dry with a soft cloth. Dried adhesive and other surface contaminates may be removed from lacquered medals with toulene (which does not disturb the lacquer coating, as stronger solvents would do). If the lacquer has worn spots, or if the item has a WATER STAIN, or if patina anomalies are present (as WIPE MARKS), or if the lacquer is cloudy, or it has been applied to thickly, to resolve any of these problems the lacquer may be removed – DELACQUERED – with a solvent as benzene. Then any patina work can be done; the object is completely dried (even baked to remove all unwanted moisture), then the object relacquered, sprayed with a new lacquer coating. This is done in most every case of REFINISHING. Original lacquer. There is absolutely no way of knowing if an existing lacquer is original – the first lacquer applied by the item’s maker. There is no reason to retain any lacquer on a medallic item if it

has any of the adverse conditions listed above. If a lacquer needs to be replaced, the item should be refinished. There is no special collector value to an original lacquer. Looking for the meaning of a numismatic word, or the description of a term? Try the Newman Numismatic Portal's Numismatic Dictionary at: https://nnp.wustl.edu/library/dictionary Printed copies of the complete Encyclopedia are available. There are 1,854 terms, on 678 pages, in The Encyclopedia of Coin and Medal Technology. Even running two a week would require more than 19 years to publish them all. Advance drafts are available for $50 postpaid with checks in U.S. funds only to Dick Johnson, 139 Thompson Drive, Torrington, CT 06790.  Wayne Homren, Editor The Numismatic Bibliomania Society is a non-profit organization promoting numismatic literature. See our web site at coinbooks.org. To submit items for publication in The E-Sylum, write to the Editor at this address: whomren@gmail.com To subscribe go to: https://my.binhost.com/lists/listinfo/esylum All Rights Reserved. NBS Home Page Contact the NBS webmaster

|