PREV ARTICLE

NEXT ARTICLE

FULL ISSUE

PREV FULL ISSUE

V11 2008 INDEX

E-SYLUM ARCHIVE

NEW TWIST ON COIN REEDING TECHNOLOGY: DIAGONAL REEDS

Timothy Grat of Moffat & Co. writes:Thank you again for another fascinating installment of

the E-Sylum. I just had to jump in on this weeks issue regarding edge

reeding. My friend Dick Johnson made a comment which no longer is true. He

wrote:

I could bring up designs applied under collar

struck reeding, such as the British colonial coin edges, where the

security marking are applied during the rimming operation and are not

obliterated during striking. But I am sure Dick is more than aware of

these pieces and was not referring to this type of operation.

I could bring up designs applied under collar

struck reeding, such as the British colonial coin edges, where the

security marking are applied during the rimming operation and are not

obliterated during striking. But I am sure Dick is more than aware of

these pieces and was not referring to this type of operation.

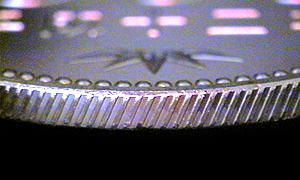

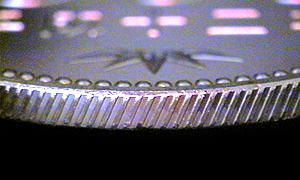

However, in direct reference to his comment,

the Japan Mint has released a 500 yen nickel-brass coin that is produced

using helical reeding. This diagonally oriented reeding is contained in

the collar which forms the coin edge upon striking. The ejection of this

coin requires a new advance in coin press technology which allows the

coining collar to rotate as the die pushes the coin out of the collar.

However, in direct reference to his comment,

the Japan Mint has released a 500 yen nickel-brass coin that is produced

using helical reeding. This diagonally oriented reeding is contained in

the collar which forms the coin edge upon striking. The ejection of this

coin requires a new advance in coin press technology which allows the

coining collar to rotate as the die pushes the coin out of the collar.

One must remember to visualize the coin that is struck is locked into the devices of the die and this in turn (pun intended) serves as the drive dog for removing the coin.

I realize that the term drive dog may be unknown to many of your readers - it is a machine tool term. A drive dog is a device that transfers rotary movement of the machine to the workpiece, in this case the rotary movement of the ratcheting ejection to the coin. If the face of the anvil die were blank, there would be no tooth to transfer the rotation to the finished coin.

Other than a blank wall aperture forming a smooth edge

coin reeding is the only edge treatment where this can occur. Obviously,

lettering or any edge ornamentation, or even diagonal lines cannot be

ejected in a coining press.

However, in direct reference to his comment,

the Japan Mint has released a 500 yen nickel-brass coin that is produced

using helical reeding. This diagonally oriented reeding is contained in

the collar which forms the coin edge upon striking. The ejection of this

coin requires a new advance in coin press technology which allows the

coining collar to rotate as the die pushes the coin out of the collar.

However, in direct reference to his comment,

the Japan Mint has released a 500 yen nickel-brass coin that is produced

using helical reeding. This diagonally oriented reeding is contained in

the collar which forms the coin edge upon striking. The ejection of this

coin requires a new advance in coin press technology which allows the

coining collar to rotate as the die pushes the coin out of the collar.

One must remember to visualize the coin that is struck is locked into the devices of the die and this in turn (pun intended) serves as the drive dog for removing the coin.

I realize that the term drive dog may be unknown to many of your readers - it is a machine tool term. A drive dog is a device that transfers rotary movement of the machine to the workpiece, in this case the rotary movement of the ratcheting ejection to the coin. If the face of the anvil die were blank, there would be no tooth to transfer the rotation to the finished coin.

Dick Johnson writes:

I was unaware of that coin press technology that ejects a

diagonal reeded coin. I am starved to learn more about it. Tell me

everything you know about it! Is that Japanese coin the first? Was this

developed privately or at one of the Japanese mints? I can indeed imagine

how this works. Clever of the Japanese to invent it.

Timothy Grat responded:

The Japanese Mint did develop the technology themselves.

They are using Schuler MRH150s, same as the US Mint. They are running

these ratcheting collars at just over 700 strokes per minute! I will grab

a still shot of the collar off some video of the Japanese Mint that my

partner Sean has. No use in grabbing a still of the striking, because at

715 SPM the camera didn't see much! The 500 yen piece is the only coin I

know of thus far that has this edge. I can only imagine there were test

pieces, but this is the first production piece. These are the same pieces

that have the latent imaging and the micro-dot technology as

well...show-offs!

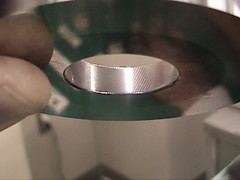

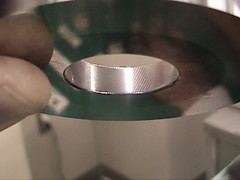

Here's an image that shows the collar itself.

This image was taken by Sean Moffatt at his visit to the Japanese Mint

during the 22nd Mint Directors Conference in Osaka.

Here's an image that shows the collar itself.

This image was taken by Sean Moffatt at his visit to the Japanese Mint

during the 22nd Mint Directors Conference in Osaka.

Here's an image that shows the collar itself.

This image was taken by Sean Moffatt at his visit to the Japanese Mint

during the 22nd Mint Directors Conference in Osaka.

Here's an image that shows the collar itself.

This image was taken by Sean Moffatt at his visit to the Japanese Mint

during the 22nd Mint Directors Conference in Osaka. Dick Johnson adds:

This is fabulous coining technology information! You have

taught me something I didn't know. This will likely be news to E-Sylum

subscribers as well.

Wayne Homren, Editor

The Numismatic Bibliomania Society is a non-profit organization promoting numismatic literature. See our web site at coinbooks.org.

To submit items for publication in The E-Sylum, write to the Editor at this address: whomren@gmail.com

To subscribe go to: https://my.binhost.com/lists/listinfo/esylum

All Rights Reserved.

NBS Home Page

Contact the NBS webmaster