PREV ARTICLE

NEXT ARTICLE

FULL ISSUE

PREV FULL ISSUE

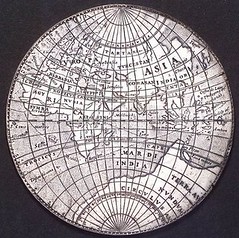

DICK JOHNSON ON HOW THE MERCATOR MAP MEDAL COULD BE REPRODUCED

Dick Johnson and John Cadorini copied me on several emails this week concerning the Mercator Map Medal and how multiple copies, each seemingly hand-engraved, could be created.

Here is Dick's final summary email to John.

-Editor

In regard to previous authorities' inability to state whether this piece was cast or struck, I can shed a little light but my opinion will not be the final word. It remains for further study, and, perhaps, some scientific analysis.

There are five possibilities of how these pieces were produced:

Each medal hand engraved remains the strongest possibility. Despite the great detail on a 69mm medal, this is easy engraving by flat engraving in contrast to relief engraving required for preparing a die for die striking. As a map publisher, Michael Mercator, would have had access to one or more such hand engravers. The same craftsman who could engrave his printing plates for printing maps could have easily engraved such a medal. Even at this time, 1589, such skilled craftsmanship was not that costly. And whatever time required to complete such a surface engraving for both sides of the medal, was not that great. Cast from a mold. Once a single specimen was obtained, a mold could have been made, and cast replicas could have been made from this mold. However, these should have shown some casting evidence no matter how small (as nodules near some detail where air bubbles would be lodged). Since none of the descriptions mentions any of this, it is less likely to have been cast. Die struck. No press existed at this time to have struck a piece this large. Electrogalvanic casting did not exist at this time. It was not developed until Moritz Herman Jacobi (1801-1874), a German physicist and engineer working in Saint Petersburg Russia developed in 1837 the electrolysis process he called "Galvanoplasty." This technology arrived in London, where the medals were made, in 1840. While the medals could have been made by this technique after this time, if they are all contemporary this possibility is eliminated. Some unknown process. Possible but slim. A pair of ersatz dies could have been made of iron with a silver blank placed between and some manor of retaining the three parts intact, a great weight could have been applied (in effect, drop forged). How large a weight I cannot speculate. This process produces less finite detail than all previous techniques mentioned. The quality of the medals leaves me to suggest each were hand engraved by one very experienced hand engraver.

To read the complete article, see:

NOTES FROM E-SYLUM READERS: JUNE 6, 2010

(www.coinbooks.org/esylum_v13n23a21.html)

The Numismatic Bibliomania Society is a non-profit organization promoting numismatic literature. See our web site at coinbooks.org. To submit items for publication in The E-Sylum, write to the Editor at this address: whomren@gmail.com To subscribe go to: https://my.binhost.com/lists/listinfo/esylum All Rights Reserved. NBS Home Page Contact the NBS webmaster

|