PREV ARTICLE

NEXT ARTICLE

FULL ISSUE

PREV FULL ISSUE

SCHULER GROUP: COIN PRESS MAKER TO THE WORLD

Another great article this week comes from the September 12, 2013 issue of CoinsWeekly, where Ursula Kampmann writes about her visit to coin press maker Schuler Group. Here's an excerpt, but be sure to read the complete article online.

-Editor

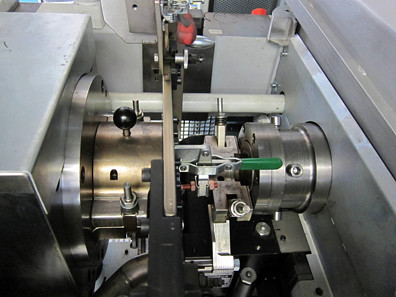

When Gustav Buschick and Theodor Choulant visited the machine works of Louis Schuler in Göppingen in April 1905, they saw as many as 30 minting machines to be delivered to China. At that time, Schuler was an established company already. It had been founded by Louis Schuler (1814-1890) in 1839. He visited the famous Great Exhibition, the very first World’s Fair, in London in 1851. There he could see how metal was processed, i.e. not time-consumingly by hand, but with the aid of huge presses. Schuler wanted to do the same in Germany, and thus started to construct machine tools for sheet metal processing in 1852. Since around 1870, Schuler has likewise been producing minting machines. That, however, constituted only a small part of the business. Horizontal Coin Minting

Horizontal coin minting To read the complete article, see: Coin minting presses for the entire world (coinsweekly.com/en/page/4?&id=2257)

Wayne Homren, Editor The Numismatic Bibliomania Society is a non-profit organization promoting numismatic literature. See our web site at coinbooks.org. To submit items for publication in The E-Sylum, write to the Editor at this address: whomren@gmail.com To subscribe go to: https://my.binhost.com/lists/listinfo/esylum All Rights Reserved. NBS Home Page Contact the NBS webmaster

|