PREV ARTICLE

NEXT ARTICLE

FULL ISSUE

PREV FULL ISSUE

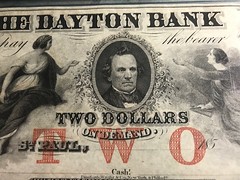

BANKNOTE PROTECTOR LETTERPRESS PRINTING  Dick Johnson submitted these notes in response to Wendell Wolka's query about the banknote protector printing process. -Editor

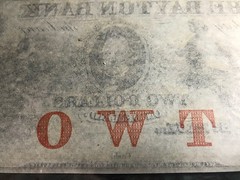

The method of printing the numbers in reverse on the back of a banknote is so simple I wonder why it appears so mysterious. The notes are printed on a flat bed press by letterpress printing. The flat bed is called a platen and it is covered with a special heavy paper call a tympan. Sheets of clean paper are fed by hand one at a time. Ink rollers apply a fresh amount of ink across the type and this is impressed on the sheet of paper. To obtain the reverse printed numbers on the back the press is cycled without a sheet of paper and the type prints on the tympan. On the next sheet it offsets on this sheet. Thus the press cycles print on paper - print on the tympan – print on paper and so on. Letterpress printing with raised type differs from the modern printing method called offset printing despite the same use of the term “offset.” I don’t know if there is a special term for this reverse numbers in the currency field. I learned about offset the hard way, by experience. When I was in high school I bought a flat bed press – a Chandler & Price press -- and did simple printing. I was constantly buying more type in different faces and sizes. I liked that press so much I bought a second one, slightly larger. But when I enlisted in the air force I sold it all to a fellow coin collector, James G. McNees, who ultimately printed the Coin Collector Digest on it. (see The E-Sylum, vol 15, no 3, article 7, January 15, 2012). Joe Boling agrees. Here's his response. -Editor

The protectors are printed by letterpress. On the old platen presses, the sheet being printed is laid into the press on top of a card backing affixed to the press bed. Pins on the card guide the placement of the sheet on two sides. The press operator would close the press on the card, thus printing on it. Then insert the sheet to be printed and close it again - presto, printing on both sides. That’s exactly how modern offset errors are created - the press closes with no paper in it, and the bed of the press gets printed. Successive sheets through the press pick up the wet ink and it appears on the wrong side in mirror image. As more sheets are printed, the wet ink fades out. That’s why offset errors on a run of consecutive numbers that do NOT fade are fakes. Back to the protectors; the operator would re-print the bed of the press frequently - maybe not for every sheet, but certainly not more than three before printing the bed again. Thanks, everyone. -Editor

To read the earlier E-Sylum articles, see:  Wayne Homren, Editor The Numismatic Bibliomania Society is a non-profit organization promoting numismatic literature. See our web site at coinbooks.org. To submit items for publication in The E-Sylum, write to the Editor at this address: whomren@gmail.com To subscribe go to: https://my.binhost.com/lists/listinfo/esylum All Rights Reserved. NBS Home Page Contact the NBS webmaster

|