PREV ARTICLE

NEXT ARTICLE

FULL ISSUE

PREV FULL ISSUE

VOCABULARY TERMS: CAST COPY, SHRINKAGEDick Johnson submitted these entries from his Encyclopedia of Coin and Medal Terminology. Thanks. -Editor

Cast Copy. Made by any method of molding; the original of which was a genuine piece. Cast copies run the gamut of authority, intent and quality; as it may be a facsimile, private copy, imitation, forgery or counterfeit. See COPIES and REPLICAS. Cast copies are always slightly less diameter than the original from which they are made due to the shrinkage in making the mold and making the cast replica. Such shrinkage ranges from 1 to 4% per generation. Poorly made

casts – or by inexperienced persons – have great porosity (bubbles, bleeps, blisters) from trapped air (causing cavitations), from dirty molds and often a greasy feel from improper knowledge of release agents. Porosity,

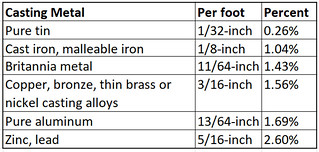

numerous bubble marks (blow holes) and lack of sharp detail are the most evident indications of a cast copy. See shrinkage. Shrinkage. A reduction in size particularly in cast objects caused by the cooling of the metal from the original size of the mold. Among the properties of each metal is its rate of contraction (molecules are drawn closer together during cooling usually in uniform rate, but uneven contraction voids are known to exist). In numismatics the most popular casting metal – bronze – can shrink form 1 1/2 to 2% in diameter. For this reason a second generation cast, or any succeeding cast (called an AFTER-CAST), can be differentiated from an original by its slightly smaller diameter. It must be remembered in all cases of shrinkage, however, that if a mold is made from the original medal the mold itself shrinks as it cools. A cast made from that mold would exhibit the combined shrinkage of both mold and cast. Thus there is no precise percentage that a second, or subsequent generation cast, can differ from the original item. Along with the shrinkage there is some loss of definition and sharpness of detail – largely due to the experience of the caster – but the most obvious criterion is the smaller diameter. See cast medals. Measurements should be carefully made. For medallic items it is best to measure from outside rim across the widest part, to that outside rim (not necessarily from edge to edge). A method of eluding shrinkage measurement is to have a wider diameter piece (easy to accomplish in casting) that could measure greater than the original!

References: CLASS 07.2 Looking for the meaning of a numismatic word, or the description of a term? Try the Newman Numismatic Portal's Numismatic Dictionary at: https://nnp.wustl.edu/library/dictionary  Wayne Homren, Editor The Numismatic Bibliomania Society is a non-profit organization promoting numismatic literature. See our web site at coinbooks.org. To submit items for publication in The E-Sylum, write to the Editor at this address: whomren@gmail.com To subscribe go to: https://my.binhost.com/lists/listinfo/esylum All Rights Reserved. NBS Home Page Contact the NBS webmaster

|