PREV ARTICLE

NEXT ARTICLE

FULL ISSUE

PREV FULL ISSUE

SORTING SILVER NICKELS AT THE U.S. MINTSAlan Meghrig alerted me to this article "From Nickel to Silver" by Robert Stahl of New York, NY in the June 2019 IEEE Life Members Newsletter. We're republishing it here with permission. Many thanks to Alan and the good people at the Institute of Electrical and Electronics Engineers (IEEE). -Editor

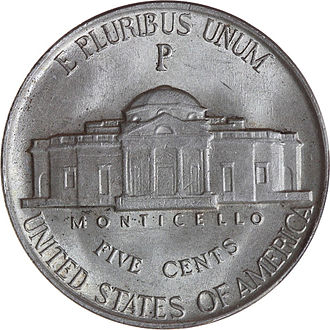

The war finally ended, and the U.S. Mint proceeded with the silver nickel retirement process, applied to coins returned by banks throughout the country. An obvious approach was to spread the mixed Jefferson coins on a moving belt and have personnel pluck coins identified by the tell-tale little mint mark. Just picture people with green eyeshades staring at this endless belt for 8 h a day. Needless to say, serious fatigue set in, resulting in an unacceptable rate of the silver coins going back into circulation. Mint management decided that there had to be a better way, putting out a request for fixed-price bids on a machine of unspecified design that would meet required productivity and error-rate criteria. Enter Berkeley Scientific Company (a designer and manufacturer of high-tech instruments with loose ties to the University of California, Berkeley), which was acquired by Beckman Instruments. As chief engineer, I looked at the mint request, and while having no idea how to implement it, I figured, "How difficult can it be to separate two different alloys?" We submitted a bid with a fairly generous safety factor in the price, and we got the job. For test purposes, the San Francisco Mint supplied us with two bags of nickels, one with silver nickels and another with regular nickels. We performed experiments to compare the two kinds of nickels, testing just about every physical parameter. Among those that I remember was the measurement of electrical resistivity by means of high-frequency eddy currents and the examination of acoustical properties when being rung like a miniature Chinese gong. The government metallurgists had done an amazing job of matching the two alloys. We could not find a difference large enough to reliably distinguish between the two, especially after the wear and tear of commerce through years of circulation. We were about to reconcile ourselves to going the complex and expensive automated spectrometer route when I decided to try one more experiment. Fighting fire with fire, we obtained a liberated radar magnet, which, when provided with specially designed pole-pieces, furnished a very intense magnetic field, suited for use with a delicate torsion balance. We then measured the force on each type of coin. Voila! A small but definite difference was found. Based on this finding, we machined a stainless-steel drum with holes in the side slightly larger in diameter than the coins. With the drum axis of rotation set at a 45° angle from the horizontal, it acted as both a hopper and feeder. When a coin reached an exactly vertical on-edge position during the rotation of the drum, only a very small force was needed to tip it. Radar magnet pole-pieces at this point provided this force, and the nickel-bearing coins tumbled into a chute. Silver nickels traveled on, where they fell into another chute. Besides the gear-motor drive, our machine had just one moving part. The San Francisco Mint was sufficiently pleased with our machine that two more were purchased, by the Philadelphia and Denver Mints, thus equipping all three coin-producing mints in the U.S. with our coin sorter. One could say that we had achieved a monopoly. I wasn't aware of any requirement to remove silver nickels from circulation, although it is of course lucrative to do so. I assumed this was just a practice of the mint to salvage silver at a lower cost. But I reached out to author and researcher David Lange for clarification. -Editor Dave writes: When the emergency coins were authorized the plan was to remove both steel cents and silver nickels after the war. Active withdrawal of the former lasted from 1949-60, at which point few steel cents remained in circulation. They had been a nuisance from the outset, making their withdrawal necessary. Conversely, the wartime nickels proved to be satisfactory in all respects, though they did wear down more quickly than the normal pieces. While there may have been a brief attempt to remove them after the war I've found no documentation that it lasted very long. War nickels were still common in circulation when I started collecting around 1965, but I never found a single steel cent.

Thanks! So where are these machines today? Still at the mints? Do modern coin sorting machines have the ability to segregate silver nickels? -Editor To read the complete June 2019 newsletter, see:

To visit the complete archive if IEEE Life Member newsletters, see:

Wayne Homren, Editor The Numismatic Bibliomania Society is a non-profit organization promoting numismatic literature. See our web site at coinbooks.org. To submit items for publication in The E-Sylum, write to the Editor at this address: whomren@gmail.com To subscribe go to: https://my.binhost.com/lists/listinfo/esylum All Rights Reserved. NBS Home Page Contact the NBS webmaster

|