PREV ARTICLE

NEXT ARTICLE

FULL ISSUE

PREV FULL ISSUE

VOCABULARY TERM: SINTERED METALDick Johnson submitted this entry from his Encyclopedia of Coin and Medal Terminology. Thanks. -Editor

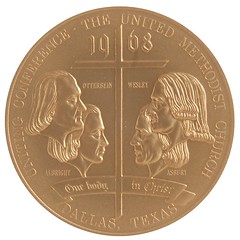

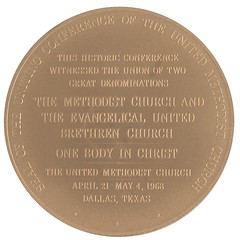

This experimental medal was made by powder metallurgy, formed by compaction and sintering. It was made for Franklin Mint, but it proved the unworthiness of this process for medal manufacture. Sintered Metal. Made by powder metallurgy. Compared to struck medals sintered medals have five percent porosity and are about a tenth the hardness. They do not take a

typical "medallic patina" finish of reliving and highlighting but must be finished with coatings. The process consists of three stages, pulverization of the metal (and mixture of several

metal elements if required), compaction, and sintering. Compaction is accomplished by extreme temperature and sintering is completed in special presses. Other than an experimental piece or two the

process is not applicable to the medallic field. The piece illustrated was created for the Franklin Mint. Wayne Homren, Editor The Numismatic Bibliomania Society is a non-profit organization promoting numismatic literature. See our web site at coinbooks.org. To submit items for publication in The E-Sylum, write to the Editor at this address: whomren@gmail.com To subscribe go to: https://my.binhost.com/lists/listinfo/esylum All Rights Reserved. NBS Home Page Contact the NBS webmaster

|